Obertshausen – Warp knitting machine builder Karl Mayer is celebrating a landmark anniversary this year, 35 years on from the development of its renowned EL pattern drive.

The KS 4 EL, the company’s first warp knitting machine featuring electronic guide bar control, was delivered on 30 November 1990 and is now regarded as a breakthrough in patterning technology.

This milestone capped a development path that began a decade earlier, when the SU gearbox with the MRS42SU initiated the shift from mechanical pattern chains to digital data and opened the door to new levels of flexibility in warp knitting.

The SU drive was first introduced on multibar raschel machines, where it controlled the shogging movement of the guide bars using a magneto‑mechanical system comprising actuators and a microcomputer.

This innovation enabled virtually unlimited repeat lengths, higher production speeds, shorter setting times and much easier handling, because pattern changes could be implemented within minutes instead of hours and no mechanical chains needed to be replaced.

In 1985 Karl Mayer expanded the concept by adding an integrated overlap device to the SU drive, making it possible to replace pattern chains and discs for guide bar control on tricot machines and preparing the ground for fully electronic solutions. These developments marked the company’s first decisive step away from purely mechanical patterning and towards software‑based control in warp knitting.

EL guide bar control breakthrough

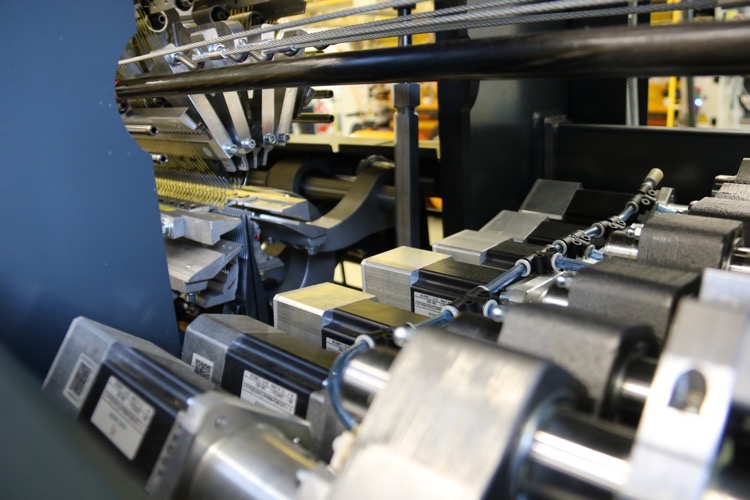

To overcome the remaining mechanical limitations of the SU drive on tricot machines, Karl Mayer’s engineers turned to electric motors and created what became known as EL guide bar control. Senior expert Georg Kraus recalls that using electric motors to move the guide bars was “completely new territory” for warp knitting, but trials with asynchronous motors and ball screws quickly proved the concept’s speed, precision and reliability.

The prototype system led to the KS 4 EL, which ushered in a new era by increasing machine speed by up to 37% compared with the SU‑equipped version while eliminating pattern discs and most mechanical constraints. Patterns could now be loaded via data transfer, and the new machines required less maintenance and floor space, making them highly attractive to both fashion and technical textile producers.

Roll‑out

Following the success on tricot equipment, Karl Mayer extended the EL drive principle to Nippon Mayer double raschel machines and to machines designed for technical textiles. Lace raschel models were converted later, culminating in the launch of the TL 66 in 2002, the first multibar raschel machine with fully electronic control of all guide bars for high‑bar applications.

The compact mechanics of these EL‑equipped multibar raschel machines allowed more guide bars to be integrated and increased the maximum shogging distance for pattern bars, significantly expanding design and patterning options compared with SU‑based configurations. This combination of higher patterning freedom and robust industrial performance helped consolidate EL technology as a core platform across Karl Mayer’s warp knitting portfolio.

Extending EL to sub‑processes

As the technology matured, Karl Mayer improved the price‑performance ratio of the EL system and began exploiting its potential for additional warp knitting sub‑processes, particularly yarn feeding. Building on EL control of the tension rail, the company developed Advanced Feeding Control (AFC), which keeps machine performance at a maximum even in complex patterns with strongly varying yarn consumption.

This approach underpinned the launch at ITMA 2023 of the market’s fastest three‑bar tricot machine with electronic guide bar control, which produced pleated fabric at 2,900 rpm during live demonstrations.

At the same show, Karl Mayer introduced the Wefttronic II G with the new Vario Weft laying system for technical textiles, a weft insertion concept that eliminates mechanical interventions in threading, removes repeat limitations and reduces edge waste, again using EL‑based technology.

For long‑time technology pioneer Georg Kraus, the journey of the EL drive is still far from over. In the medium term he expects EL solutions to completely replace N pattern drives and sees further opportunities for electronic control concepts across the entire warp knitting machine spectrum.

With the 1990 delivery of the KS 4 EL as a reference point, Karl Mayer is using this anniversary year to underline how electronic guide bar control has transformed patterning from a gear‑driven process into a digital, data‑driven discipline with vast creative and industrial potential.